PDF Publication Title:

Text from PDF Page: 002

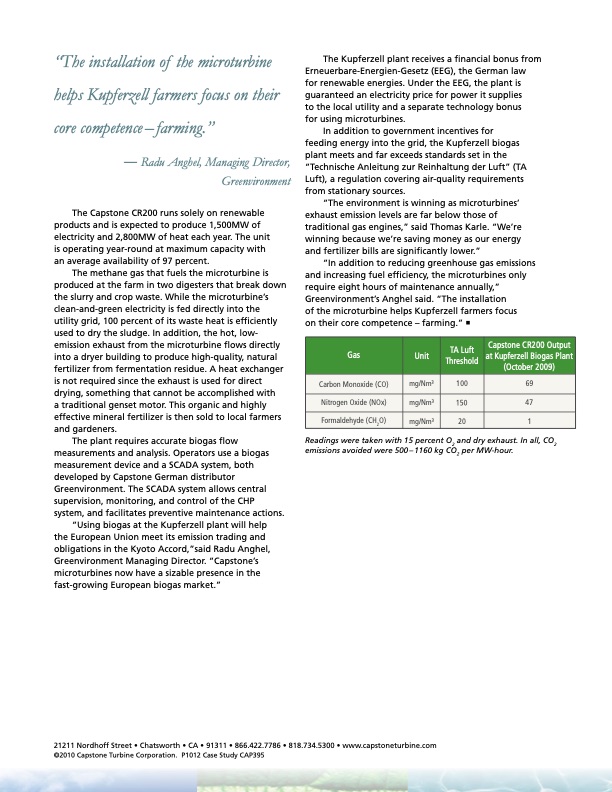

“The installation of the microturbine helps Kupferzell farmers focus on their core competence – farming.” — Radu Anghel, Managing Director, Greenvironment The Capstone CR200 runs solely on renewable products and is expected to produce 1,500MW of electricity and 2,800MW of heat each year. The unit is operating year-round at maximum capacity with an average availability of 97 percent. The methane gas that fuels the microturbine is produced at the farm in two digesters that break down the slurry and crop waste. While the microturbine’s clean-and-green electricity is fed directly into the utility grid, 100 percent of its waste heat is efficiently used to dry the sludge. In addition, the hot, low- emission exhaust from the microturbine flows directly into a dryer building to produce high-quality, natural fertilizer from fermentation residue. A heat exchanger is not required since the exhaust is used for direct drying, something that cannot be accomplished with a traditional genset motor. This organic and highly effective mineral fertilizer is then sold to local farmers and gardeners. The plant requires accurate biogas flow measurements and analysis. Operators use a biogas measurement device and a SCADA system, both developed by Capstone German distributor Greenvironment. The SCADA system allows central supervision, monitoring, and control of the CHP system, and facilitates preventive maintenance actions. “Using biogas at the Kupferzell plant will help the European Union meet its emission trading and obligations in the Kyoto Accord,”said Radu Anghel, Greenvironment Managing Director. “Capstone’s microturbines now have a sizable presence in the fast-growing European biogas market.” The Kupferzell plant receives a financial bonus from Erneuerbare-Energien-Gesetz (EEG), the German law for renewable energies. Under the EEG, the plant is guaranteed an electricity price for power it supplies to the local utility and a separate technology bonus for using microturbines. In addition to government incentives for feeding energy into the grid, the Kupferzell biogas plant meets and far exceeds standards set in the “Technische Anleitung zur Reinhaltung der Luft” (TA Luft), a regulation covering air-quality requirements from stationary sources. “The environment is winning as microturbines’ exhaust emission levels are far below those of traditional gas engines,” said Thomas Karle. “We’re winning because we’re saving money as our energy and fertilizer bills are significantly lower.” “In addition to reducing greenhouse gas emissions and increasing fuel efficiency, the microturbines only require eight hours of maintenance annually,” Greenvironment’s Anghel said. “The installation of the microturbine helps Kupferzell farmers focus on their core competence – farming.” Readings were taken with 15 percent O2 and dry exhaust. In all, CO2 emissions avoided were 500 – 1160 kg CO2 per MW-hour. Gas Unit TA Luft Threshold Capstone CR200 Output at Kupferzell Biogas Plant (October 2009) Carbon Monoxide (CO) mg/Nm3 100 69 Nitrogen Oxide (NOx) mg/Nm3 150 47 Formaldehyde (CH2O) mg/Nm3 20 1 21211 Nordhoff Street • Chatsworth • CA • 91311 • 866.422.7786 • 818.734.5300 • www.capstoneturbine.com ©2010 Capstone Turbine Corporation. P1012 Case Study CAP395PDF Image | Agricultural Kupferzell Agricultural Biogas Plant

PDF Search Title:

Agricultural Kupferzell Agricultural Biogas PlantOriginal File Name Searched:

CS_CAP395_Kupferzell_Biogas_Plant_lowires.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |