PDF Publication Title:

Text from PDF Page: 002

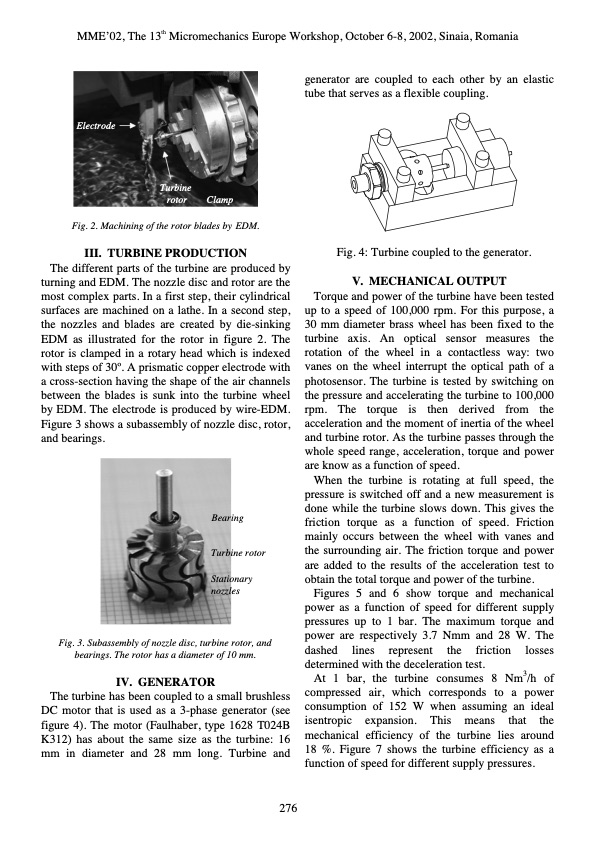

th MME’02, The 13 Micromechanics Europe Workshop, October 6-8, 2002, Sinaia, Romania Electrode Turbine rotor Clamp Fig. 2. Machining of the rotor blades by EDM. III. TURBINE PRODUCTION The different parts of the turbine are produced by turning and EDM. The nozzle disc and rotor are the most complex parts. In a first step, their cylindrical surfaces are machined on a lathe. In a second step, the nozzles and blades are created by die-sinking EDM as illustrated for the rotor in figure 2. The rotor is clamped in a rotary head which is indexed with steps of 30o. A prismatic copper electrode with a cross-section having the shape of the air channels between the blades is sunk into the turbine wheel by EDM. The electrode is produced by wire-EDM. Figure 3 shows a subassembly of nozzle disc, rotor, and bearings. Bearing Turbine rotor Stationary nozzles Fig. 3. Subassembly of nozzle disc, turbine rotor, and bearings. The rotor has a diameter of 10 mm. IV. GENERATOR The turbine has been coupled to a small brushless DC motor that is used as a 3-phase generator (see figure 4). The motor (Faulhaber, type 1628 T024B K312) has about the same size as the turbine: 16 mm in diameter and 28 mm long. Turbine and Fig. 4: Turbine coupled to the generator. V. MECHANICAL OUTPUT Torque and power of the turbine have been tested up to a speed of 100,000 rpm. For this purpose, a 30 mm diameter brass wheel has been fixed to the turbine axis. An optical sensor measures the rotation of the wheel in a contactless way: two vanes on the wheel interrupt the optical path of a photosensor. The turbine is tested by switching on the pressure and accelerating the turbine to 100,000 rpm. The torque is then derived from the acceleration and the moment of inertia of the wheel and turbine rotor. As the turbine passes through the whole speed range, acceleration, torque and power are know as a function of speed. When the turbine is rotating at full speed, the pressure is switched off and a new measurement is done while the turbine slows down. This gives the friction torque as a function of speed. Friction mainly occurs between the wheel with vanes and the surrounding air. The friction torque and power are added to the results of the acceleration test to obtain the total torque and power of the turbine. Figures 5 and 6 show torque and mechanical power as a function of speed for different supply pressures up to 1 bar. The maximum torque and power are respectively 3.7 Nmm and 28 W. The dashed lines represent the friction losses determined with the deceleration test. 3 At 1 bar, the turbine consumes 8 Nm /h of compressed air, which corresponds to a power consumption of 152 W when assuming an ideal isentropic expansion. This means that the mechanical efficiency of the turbine lies around 18 %. Figure 7 shows the turbine efficiency as a function of speed for different supply pressures. generator are coupled to each other by an elastic tube that serves as a flexible coupling. 276PDF Image | A MICROTURBINE FOR ELECTRIC POWER GENERATION

PDF Search Title:

A MICROTURBINE FOR ELECTRIC POWER GENERATIONOriginal File Name Searched:

Paper_MME2002_turbine.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |