PDF Publication Title:

Text from PDF Page: 060

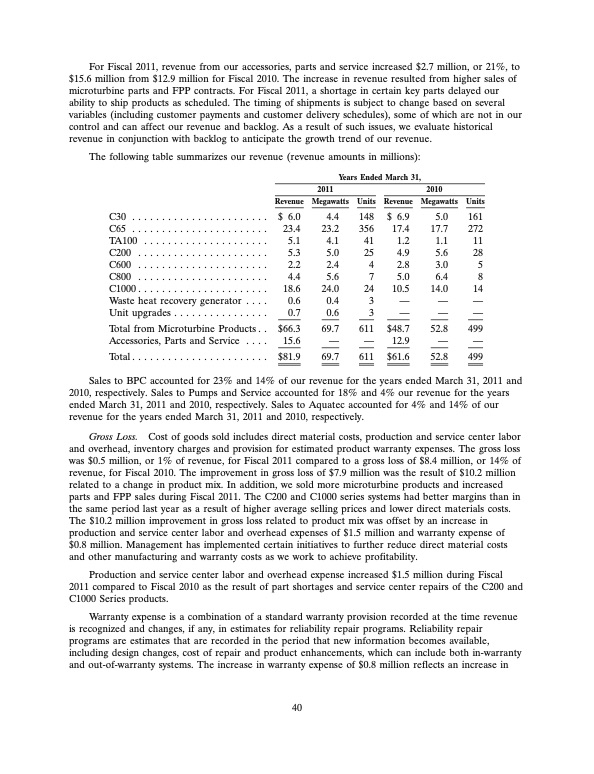

For Fiscal 2011, revenue from our accessories, parts and service increased $2.7 million, or 21%, to $15.6 million from $12.9 million for Fiscal 2010. The increase in revenue resulted from higher sales of microturbine parts and FPP contracts. For Fiscal 2011, a shortage in certain key parts delayed our ability to ship products as scheduled. The timing of shipments is subject to change based on several variables (including customer payments and customer delivery schedules), some of which are not in our control and can affect our revenue and backlog. As a result of such issues, we evaluate historical revenue in conjunction with backlog to anticipate the growth trend of our revenue. The following table summarizes our revenue (revenue amounts in millions): Years Ended March 31, Revenue Megawatts Units Revenue Megawatts Units C30 ....................... C65 ....................... TA100 ..................... C200 ...................... C600 ...................... C800 ...................... C1000...................... Waste heat recovery generator . . . . Unit upgrades . . . . . . . . . . . . . . . . Total from Microturbine Products . . Accessories, Parts and Service . . . . Total....................... $ 6.0 23.4 5.1 5.3 2.2 4.4 18.6 0.6 0.7 $66.3 15.6 $81.9 2011 4.4 148 $ 6.9 23.2 356 17.4 4.1 41 1.2 5.0 25 4.9 2.4 4 2.8 5.6 7 5.0 24.0 24 10.5 0.4 3 — 0.6 3 — 69.7 611 $48.7 —— 12.9 69.7 611 $61.6 2010 5.0 161 17.7 272 1.1 11 5.6 28 3.0 5 6.4 8 14.0 14 — — — — 52.8 499 — — 52.8 499 Sales to BPC accounted for 23% and 14% of our revenue for the years ended March 31, 2011 and 2010, respectively. Sales to Pumps and Service accounted for 18% and 4% our revenue for the years ended March 31, 2011 and 2010, respectively. Sales to Aquatec accounted for 4% and 14% of our revenue for the years ended March 31, 2011 and 2010, respectively. Gross Loss. Cost of goods sold includes direct material costs, production and service center labor and overhead, inventory charges and provision for estimated product warranty expenses. The gross loss was $0.5 million, or 1% of revenue, for Fiscal 2011 compared to a gross loss of $8.4 million, or 14% of revenue, for Fiscal 2010. The improvement in gross loss of $7.9 million was the result of $10.2 million related to a change in product mix. In addition, we sold more microturbine products and increased parts and FPP sales during Fiscal 2011. The C200 and C1000 series systems had better margins than in the same period last year as a result of higher average selling prices and lower direct materials costs. The $10.2 million improvement in gross loss related to product mix was offset by an increase in production and service center labor and overhead expenses of $1.5 million and warranty expense of $0.8 million. Management has implemented certain initiatives to further reduce direct material costs and other manufacturing and warranty costs as we work to achieve profitability. Production and service center labor and overhead expense increased $1.5 million during Fiscal 2011 compared to Fiscal 2010 as the result of part shortages and service center repairs of the C200 and C1000 Series products. Warranty expense is a combination of a standard warranty provision recorded at the time revenue is recognized and changes, if any, in estimates for reliability repair programs. Reliability repair programs are estimates that are recorded in the period that new information becomes available, including design changes, cost of repair and product enhancements, which can include both in-warranty and out-of-warranty systems. The increase in warranty expense of $0.8 million reflects an increase in 40PDF Image | 2011 Annual Report Capstone Turbine Corporation

PDF Search Title:

2011 Annual Report Capstone Turbine CorporationOriginal File Name Searched:

Capstone-AR2011.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |