PDF Publication Title:

Text from PDF Page: 001

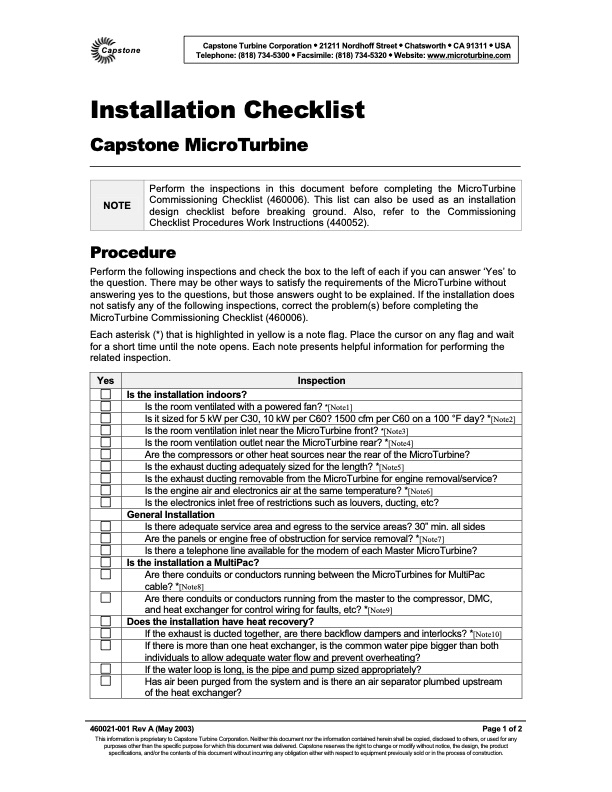

Capstone Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Telephone: (818) 734-5300 • Facsimile: (818) 734-5320 • Website: www.microturbine.com Installation Checklist Capstone MicroTurbine Procedure Perform the following inspections and check the box to the left of each if you can answer ‘Yes’ to the question. There may be other ways to satisfy the requirements of the MicroTurbine without answering yes to the questions, but those answers ought to be explained. If the installation does not satisfy any of the following inspections, correct the problem(s) before completing the MicroTurbine Commissioning Checklist (460006). Each asterisk (*) that is highlighted in yellow is a note flag. Place the cursor on any flag and wait for a short time until the note opens. Each note presents helpful information for performing the related inspection. Is the installation indoors? Is the room ventilated with a powered fan? *[Note1] Is it sized for 5 kW per C30, 10 kW per C60? 1500 cfm per C60 on a 100 °F day? *[Note2] Is the room ventilation inlet near the MicroTurbine front? *[Note3] Is the room ventilation outlet near the MicroTurbine rear? *[Note4] Are the compressors or other heat sources near the rear of the MicroTurbine? Is the exhaust ducting adequately sized for the length? *[Note5] Is the exhaust ducting removable from the MicroTurbine for engine removal/service? Is the engine air and electronics air at the same temperature? *[Note6] Is the electronics inlet free of restrictions such as louvers, ducting, etc? General Installation Is there adequate service area and egress to the service areas? 30” min. all sides Are the panels or engine free of obstruction for service removal? *[Note7] Is there a telephone line available for the modem of each Master MicroTurbine? Is the installation a MultiPac? Are there conduits or conductors running between the MicroTurbines for MultiPac cable? *[Note8] Are there conduits or conductors running from the master to the compressor, DMC, and heat exchanger for control wiring for faults, etc? *[Note9] Does the installation have heat recovery? If the exhaust is ducted together, are there backflow dampers and interlocks? *[Note10] If there is more than one heat exchanger, is the common water pipe bigger than both individuals to allow adequate water flow and prevent overheating? If the water loop is long, is the pipe and pump sized appropriately? Has air been purged from the system and is there an air separator plumbed upstream of the heat exchanger? 460021-001 Rev A (May 2003) Page 1 of 2 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. NOTE Perform the inspections in this document before completing the MicroTurbine Commissioning Checklist (460006). This list can also be used as an installation design checklist before breaking ground. Also, refer to the Commissioning Checklist Procedures Work Instructions (440052). Yes InspectionPDF Image | Installation Checklist Capstone MicroTurbine

PDF Search Title:

Installation Checklist Capstone MicroTurbineOriginal File Name Searched:

460021_Installation_Checklist.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |